Yes, you can cut pressure treated wood, but it is recommended to use a carbide-tipped circular saw blade to ensure clean and accurate cuts. Pressure treated wood contains chemicals that can be abrasive and dull a standard blade quickly.

Additionally, when cutting pressure treated wood, it is important to follow safe handling practices, such as wearing a dust mask, goggles, and gloves, and washing hands and work clothes thoroughly after handling. It is also important to note that cut edges of pressure treated lumber may not have the same level of protection as the rest of the wood, so it is recommended to seal the cut ends to prevent moisture and decay.

Overall, cutting pressure treated wood requires special attention and caution to ensure both a proper cut and safety.

Cutting Pressure Treated Wood

When it comes to cutting pressure treated wood, it’s best to use a carbide-tipped circular saw blade to avoid dulling a standard blade due to the abrasive chemicals in the wood. Safety precautions such as wearing a dust mask, goggles, and gloves should also be taken.

Cutting Pressure Treated Wood With A Hand Saw

Cutting pressure treated wood with a hand saw is a feasible option if you don’t have access to power tools. While it may require more effort, it can be done effectively by following a few steps and taking necessary precautions. To cut pressure treated wood with a hand saw, you will need the following tools and materials:

– Hand saw: Choose a saw with a fine-toothed blade for smoother cuts.

– Safety goggles and gloves: Protect your eyes and hands from potential hazards.

– Pencil or marking tool: Mark the area you want to cut for precision.

– Clamps: Secure the wood piece to a stable surface to prevent movement and ensure accurate cuts.

Follow these steps to cut pressure treated wood with a hand saw:

- Measure and mark the desired cut line on the wood. Double-check your measurements to avoid any mistakes.

- Secure the wood piece with clamps to a stable surface, such as a workbench or sawhorse. Ensure it is steady and won’t move during the cutting process.

- Position the hand saw at the marked cut line and apply gentle pressure to start the cut.

- Continue sawing along the marked line, maintaining a steady pace and smooth strokes.

- Once you have completed the cut, carefully release the clamps and inspect the wood for any rough areas or splinters.

Note: Cutting pressure treated wood with a hand saw can be time-consuming and physically demanding. Consider using power tools for larger projects or if you need to make multiple cuts.

Cutting Pressure Treated Wood With A Circular Saw

Using a circular saw to cut pressure treated wood provides faster and more precise cuts compared to a hand saw. However, it is important to take precautions and follow the correct techniques to ensure safety and achieve the desired results. To cut pressure treated wood with a circular saw, follow these steps:

- Ensure you have the necessary tools and materials:

- Circular saw: Choose a saw with a carbide-tipped blade for cutting pressure treated wood.

- Safety goggles and gloves: Protect your eyes and hands from potential hazards.

- Measuring tape and marking tool: Measure and mark the desired cut line accurately.

- Clamps: Secure the wood piece to a stable surface for stability.

- Measure and mark the cut line on the pressure treated wood, ensuring precise measurements.

- Secure the wood piece using clamps, making sure it is stable and won’t move during the cutting process.

- Adjust the circular saw to the desired depth of cut, following the manufacturer’s instructions.

- Ensure the blade is properly aligned with the marked cut line.

- Turn on the circular saw and slowly guide it along the marked cut line, applying steady and even pressure.

- Once you have completed the cut, turn off the circular saw and allow the blade to come to a complete stop before removing it from the wood.

- Inspect the cut wood for any rough areas or splinters before continuing with your project.

Cutting Pressure Treated Wood On A Table Saw

A table saw provides stability and precise cuts when cutting pressure treated wood. However, it is crucial to follow safety precautions and use the correct techniques to prevent accidents or damage. To cut pressure treated wood on a table saw, consider the following safety precautions and techniques:

- Ensure you have the necessary tools and materials:

- Table saw: Use a table saw with a carbide-tipped blade suitable for pressure treated wood.

- Safety goggles and gloves: Protect your eyes and hands from potential hazards.

- Measuring tape and marking tool: Measure and mark the desired cut line accurately.

- Push stick: Use a push stick to guide the wood through the saw while keeping your hands away from the blade.

- Featherboards: Install featherboards to ensure the wood remains tight against the table saw fence during the cut.

- Measure and mark the cut line on the pressure treated wood, ensuring precise measurements.

- Adjust the table saw blade height to match the desired depth of cut.

- Align the blade with the marked cut line and adjust the fence to ensure proper clearance.

- Put on safety goggles and gloves before turning on the table saw.

- Use a push stick to guide the wood through the blade, maintaining a steady pace and applying even pressure.

- Ensure the wood remains tight against the fence by using featherboards.

- Once the cut is complete, turn off the table saw and wait for the blade to stop before removing the wood.

Cutting Pressure Treated Wood By Hand

Cutting pressure treated wood by hand requires manual tools and techniques. Although it may be more time-consuming, it can be effective for smaller projects or when you don’t have access to power tools. When cutting pressure treated wood by hand, consider the following tools and techniques:

- Hand saw: Choose a fine-toothed hand saw for cleaner cuts.

- Safety goggles and gloves: Protect your eyes and hands from potential hazards.

- Measuring tape and marking tool: Measure and mark the desired cut line for accuracy.

- Clamps: Secure the wood piece to a stable surface to prevent movement during cutting.

- Use a pencil or marking tool to indicate the cut line on the pressure treated wood.

- Secure the wood piece with clamps to a stable surface, such as a workbench or sawhorse.

- Position the hand saw at the marked cut line and apply gentle pressure to start the cut.

- Continue sawing along the marked line, maintaining a steady pace and smooth strokes.

- After completing the cut, release the clamps and inspect the wood for any rough areas or splinters.

Credit: www.pocobuildingsupplies.com

Sealing And Protecting Cut Ends

When cutting pressure treated wood, it is important to seal and protect the cut ends. This helps prevent moisture penetration and extends the lifespan of the wood. Use a carbide-tipped circular saw blade for the best results.

Sealing and Protecting Cut Ends:

Cutting pressure treated wood is a common practice when working on various woodworking projects. However, it is essential to seal and protect the cut ends of pressure treated wood to ensure its longevity and prevent moisture penetration. Sealing the cut ends of pressure treated wood helps to maintain the effectiveness of the treatment and prevent water damage, rot, and decay. In this article, we will discuss the importance of sealing cut ends of pressure treated wood and recommend some reliable end cut sealers that you can consider using.

Importance Of Sealing Cut Ends Of Pressure Treated Wood

When pressure treated wood is cut, it exposes untreated wood that is vulnerable to moisture, insects, and decay. Sealing the cut ends helps to maintain the integrity of the treatment, ensuring long-lasting protection. The moisture content of untreated wood can quickly increase, leading to potential damage and compromising the structural integrity of your project. Sealing the cut ends helps prevent these issues, making it an essential step in working with pressure treated wood.

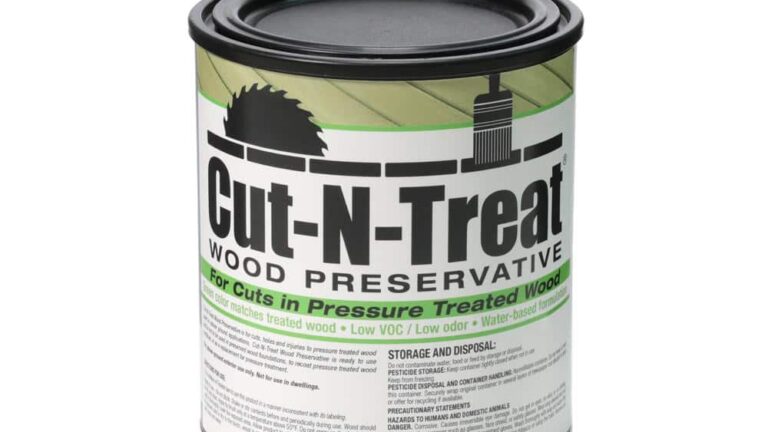

Recommended End Cut Sealers For Pressure Treated Wood

There are several reliable end cut sealers available in the market that you can use to protect and seal the cut ends of pressure treated wood. Here are some top recommendations:

| Sealer | Description |

|---|---|

| Penashield Clear Wood Preservative | A clear wood preservative that provides long-lasting protection against fungal decay, rot, and insects. |

| Woodlife Coppercoat Green Wood Preservative | A copper-based green wood preservative that offers excellent protection and extends the life of pressure treated wood. |

| Wolman WoodLife CopperCoat Wood Preservative | A copper-based wood preservative that provides protection against termites, mold, mildew, and rot. |

| Wolman Green Below Ground Wood Preservative | A below-ground wood preservative that offers long-lasting protection against subterranean termites and fungal decay. |

| DeckWise Ipe Seal End Grain Seal | An end grain seal specifically designed for hardwoods like Ipe to prevent checking, splitting, and decay. |

| Rockler Green Wood End Sealer | A water-based end sealer that helps to minimize cracking and checking in freshly cut green wood. |

| Seal Ends Once Wood End Sealer | A clear, water-based formula that provides protection against moisture, rot, and decay. |

| Rainguard Water Concentrate Timber Treatment | A water-based timber treatment that deeply penetrates the wood surface, providing long-term protection against moisture and decay. |

| Anchorseal Classic Log & Lumber End Sealer | A wax-based end sealer that forms a protective barrier against moisture loss and helps prevent end checking and splitting. |

Using any of these recommended end cut sealers will help extend the life of your pressure treated wood, ensuring its durability and resistance to decay, insect attack, and moisture damage. Remember to follow the manufacturer’s instructions for application and re-application as necessary.

By sealing the cut ends of pressure treated wood, you can protect your woodworking projects and enhance their longevity. Make sure to consider one of these top-quality end cut sealers to ensure long-lasting protection and maintain the quality of your pressure treated wood.

Safety Guidelines For Cutting Pressure Treated Wood

When it comes to cutting pressure treated wood, it’s important to follow safety guidelines. Always wear a dust mask, goggles, and gloves when handling the wood. Use a carbide-tipped circular saw blade for the best results. Wash your hands and work clothes separately after working with treated wood to avoid contamination.

When it comes to cutting pressure treated wood, it is essential to follow safety guidelines to protect yourself and ensure a successful project. In this section, we will discuss some important practices to keep in mind while handling pressure treated wood.

Safe Handling Practices When Working With Pressure Treated Wood

Working with pressure treated wood involves exposure to chemicals that can be harmful to health. To minimize risks, it is important to implement safe handling practices. Here are some guidelines to follow:

- Wearing a dust mask and goggles: When cutting or sanding pressure treated wood, it releases tiny particles and chemicals into the air. Protect your respiratory system and eyes by wearing a dust mask and goggles.

- Wearing gloves: Pressure treated wood is often wet and can cause splinters or irritate the skin. Wearing gloves will not only prevent injuries but also minimize direct contact with the chemicals.

- Washing hands thoroughly: After working with pressure treated wood, thoroughly wash your hands with mild soap and water. This will help remove any lingering chemicals and reduce the risk of ingestion or skin absorption.

- Washing work clothes separately: To prevent cross-contamination, it is recommended to wash your work clothes separately from other clothes. This ensures that any potential chemicals present on the clothes do not spread.

By following these safety guidelines, you can minimize the risks associated with handling pressure treated wood and ensure a safe working environment. Remember, the health and well-being of yourself and those around you should always be a top priority.

Recommended Blade For Cutting Pressure Treated Wood

When cutting pressure treated wood, it is recommended to use a carbide-tipped circular saw blade. This type of blade is more durable and can withstand the abrasive chemicals found in pressure treated wood, ensuring a clean and precise cut.

Best Type Of Blade For Cutting Pressure Treated Wood

When it comes to cutting pressure treated wood, using the right blade is crucial for achieving clean and precise cuts. The best type of blade for this task is a carbide-tipped circular saw blade. This type of blade is specifically designed to withstand the abrasive nature of pressure treated wood and is capable of cutting through it effortlessly, ensuring a smooth and professional finish.

Benefits Of Using A Carbide-tipped Circular Saw Blade

There are several benefits of using a carbide-tipped circular saw blade for cutting pressure treated wood. Here are a few key advantages:

- Durability: Carbide-tipped blades are known for their exceptional durability. The carbide tips on these blades are extremely hard and can withstand the abrasive nature of pressure treated wood without getting worn down easily.

- Efficiency: The sharpness of carbide-tipped blades allows for fast and efficient cutting through pressure treated wood. This helps to save time and effort during your woodworking projects.

- Smooth cuts: The precision and sharpness of carbide-tipped blades result in clean and smooth cuts. This is crucial when working with pressure treated wood as it ensures a professional-looking finish.

- Reduced kickback: Carbide-tipped blades are less prone to kickback compared to other types of blades. This enhances safety and minimizes the risk of accidents while cutting pressure treated wood.

- Long-lasting: Due to their durability, carbide-tipped blades have a longer lifespan compared to other types of blades. This means that you can use the same blade for multiple projects, saving you money in the long run.

Importance Of Using A Blade Specifically Designed For Pressure Treated Wood

Using a blade specifically designed for cutting pressure treated wood is essential for several reasons. Firstly, pressure treated wood contains chemicals that make it more resistant to decay and insect damage. These chemicals can be abrasive and can quickly dull a standard blade, leading to poor cutting performance and potentially damaging the wood.

Additionally, blades designed for pressure treated wood often have special coatings or features that help prevent corrosion from the chemicals in the wood. This ensures that the blade remains in good condition for longer, further enhancing its durability and effectiveness.

In conclusion, when working with pressure treated wood, it is highly recommended to use a carbide-tipped circular saw blade. This type of blade offers numerous benefits, such as durability, efficiency, smooth cuts, reduced kickback, and a long lifespan. By using a blade specifically designed for pressure treated wood, you can ensure better cutting performance and a professional-looking finish in your woodworking projects.

Federal Guidelines For Using Pressure Treated Wood

When it comes to cutting pressure treated wood, it is recommended to use a carbide-tipped circular saw blade. This type of blade is best suited for cutting through the chemical-treated wood, which can be abrasive and dull a standard blade quickly.

Follow these guidelines to ensure safe and precise cuts.

Important Restrictions And Recommendations For Using Treated Lumber

When it comes to using pressure treated wood, there are important restrictions and recommendations outlined by federal guidelines. These guidelines exist to ensure the safety and well-being of individuals as well as the environment. Here are some key restrictions and recommendations to keep in mind when working with pressure treated lumber:

- Refrain from using any type of treated wood where the wood will come into direct or indirect contact with drinking water supplies. This is to protect the quality and purity of the water supply, as the chemicals used in pressure treated wood can potentially leach into the water.

- Avoid using treated wood where the wood will come into contact with human or animal food. This includes surfaces such as cutting boards or food storage shelves. The chemicals in pressure treated wood can contaminate the food and pose health risks if ingested.

- Do not use treated wood near beehives or in any application where bees may come into contact with the wood. Bees are sensitive creatures, and the chemicals in pressure treated wood can harm them.

It is essential to adhere to these restrictions to ensure the safety of individuals and the protection of the environment. By taking these precautions, we can minimize the risks associated with using pressure treated wood and create a safer living environment for everyone.

Prohibition On Using Treated Wood In Certain Applications

When working with pressure treated wood, it is important to understand that there are certain applications where its use is strictly prohibited. These include:

- Direct or indirect contact with drinking water supplies: Pressure treated wood should never be used in any application where it may come into contact with drinking water supplies. This includes water storage tanks, wells, or any structures that are involved in the transportation or storage of drinking water.

- Contact with human or animal food: Treated wood should never be used in any application where it may come into contact with human or animal food. This includes cutting boards, food storage shelves, or any surface that may come into contact with edible items.

- Beehives: Pressure treated wood should never be used near beehives or in any application where bees may come into contact with the wood. The chemicals in treated wood can be toxic to bees and can harm their health and overall population.

It is crucial to be aware of these prohibitions to ensure the safety of both humans and the environment. By avoiding the use of pressure treated wood in these applications, we can prevent potential harm and maintain the integrity of our water supply, food sources, and bee populations.

Protection Of Drinking Water Supplies And Food Safety Considerations

One of the primary focuses of the federal guidelines for using pressure treated wood is the protection of drinking water supplies and food safety. These measures are essential to safeguard the quality and safety of our water and food sources. Considerations include:

- Avoiding direct or indirect contact with drinking water supplies: Pressure treated wood should never be used in any application where it may leach chemicals into drinking water supplies. This can be accomplished by using alternative materials for structures involved in the transportation or storage of drinking water.

- Preventing contact with human or animal food: Treated wood should not come into contact with human or animal food as the chemicals in pressure treated wood can contaminate the food and pose health risks. Using non-treated materials for surfaces involving food contact is the recommended course of action.

- Ensuring food safety: By adhering to proper food safety practices, such as using suitable materials for food preparation and storage surfaces, we can maintain the safety and integrity of the food we consume.

These considerations play a vital role in preserving the quality and safety of our drinking water and food sources. By following the federal guidelines for using pressure treated wood, we can contribute to a healthier and safer environment for everyone.

Frequently Asked Questions Of Can You Cut Pressure Treated Wood

Is It Safe To Cut Pressure Treated Lumber?

Yes, it is safe to cut pressure treated lumber. When cutting pressure treated wood, it is recommended to wear a dust mask, goggles, and gloves for safety. The best type of blade to use is a carbide-tipped circular saw blade, as the chemicals in the wood can dull a standard blade.

Remember to wash hands thoroughly after handling treated wood.

What Is Recommended When Cutting Pressure Treated Lumber?

When cutting pressure treated lumber, it is recommended to use a carbide-tipped circular saw blade. This type of blade is best suited for cutting through the chemicals in pressure treated wood, which can dull standard blades quickly. Remember to wear protective gear such as a dust mask, goggles, and gloves and wash hands and work clothes thoroughly after handling treated wood.

What Should Never Be Done With Pressure Treated Wood?

When working with pressure treated wood, there are certain things you should never do: 1. Avoid using pressure treated wood in areas where it will come into contact with drinking water or food. 2. Do not use pressure treated wood for beehives.

3. Refrain from cutting pressure treated wood indoors to prevent sawdust from settling. Remember to follow these guidelines for safe and proper use of pressure treated wood.

Is Pressure Treated Wood More Difficult To Cut?

Pressure treated wood is not much harder to cut. It may be slightly heavier and can be more like cutting wet wood, but it usually cuts just fine. A carbide-tipped circular saw blade is recommended for cutting pressure treated wood.

However, it’s important to wear protective gear such as a dust mask, goggles, and gloves when working with treated wood.

Conclusion

Cutting pressure treated wood can be done safely and effectively with the right tools and precautions. It is important to wear protective gear such as a dust mask, goggles, and gloves when working with this type of wood. The best type of blade for cutting pressure treated wood is a carbide-tipped circular saw blade, as it can withstand the abrasive chemicals in the wood.

Additionally, it is recommended to seal the cut ends of pressure treated wood to ensure its longevity. By following these guidelines, you can successfully cut pressure treated wood for your projects.